Time-Tested Materials, Third Party Verified Performance

- The elastomer backing is manufactured from Newman’s famous polymer-rich 2107 EPDM compound.

- The TFMTM facing of the diaphragm is made from time proven 3MTM/DyneonTM modified PTFE, the choice of the diaphragm valve industry for pharmaceutical applications and validated for years. Manufacturer certified USP Class VI.

- Mechanical exposure testing by Newman and third party industry experts to 500 steam cycles and over 100,000 valve cycles has demonstrated exceptional steam resistance and long term durability. Newman’s backings are shown to impart outstanding sealing properties at the lowest bonnet torque values.

Contact our Specialists at Newman

Newman Sanitary Gasket Company’s mission is to continually grow in our ability to meet our customers’ needs and improve our capabilities. We strive for excellence in quality, service, supply, distribution, and product development and performance. You can count on Newman Sanitary Gasket Company as your number one provider for all your gasket needs.

Certified Peace of Mind and Ground Breaking Traceability

- Each diaphragm meets the requirements of FDA CFR Title 21 177.2600 (elastomers) and paragraph 177.1550 (perfluorocarbons) and USP Class VI.

- Setting a new standard for traceability and causing a stir across the industry, every diaphragm is fully batch traceable at the part level, an exclusive in the industry (patent pending). This means that you will know the exact style, size, composition and provenance of every diaphragm in your system, simply by looking at the back of the diaphragm.

- Each diaphragm is backed by Newman’s unbeatable 45 year history in manufacturing of premium elastomer parts for the pharmaceutical industry.

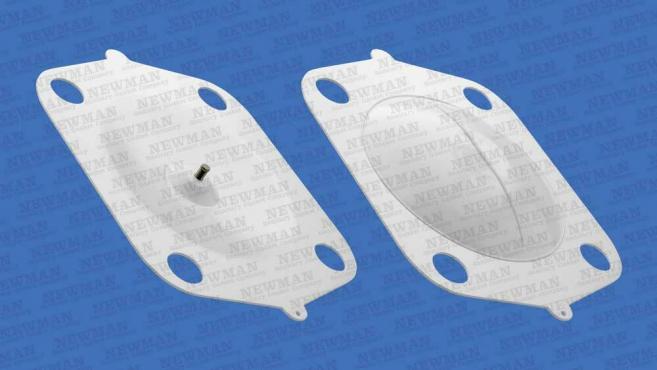

Elastomer Backed Two Piece TFM™ Diaphragms for Gemü™ Valves

Genuine Newman 2107 EPDM (Ethylene Propylene Diene Monomer)

Genuine Newman 2107 EPDM is the material of choice for many food and biopharma processing applications, surpassing other EPDM’s on the market for decades in performance and reliability. An excellent general purpose elastomer, resistant to many chemicals, polar solvents, many CIP solutions,

and most aqueous-based systems. When used as a backing in two-piece diaphragms, Newman 2107 has been shown to impart outstanding sealing properties at the lowest bonnet torque values, a substantial improvement over OEM parts.

Genuine Dyneon™ TFM™ (Modified PTFE) with Elastomer Backing

Genuine Dyneon™ TFM™ from 3M® when used in conjunction with Newman’s proprietary processing has resulted in the highest chemical resistance and the lowest permeability and makes it ideal for almost all processing conditions where extended service life is desired. It is resistant to almost all chemicals, solvents, and CIP solutions, and has been tested to 500 one-hour steam cycles/100,000 valve cycles in many valve configurations. It is ideal for continuous steam, hot WFI and processing areas. These diaphragms are shipped together with a paired elastomer backing piece made of Newman 2107 EPDM.

- Temperature Range (with EPDM backing): -20°F (-28°C) to 300°F (148°C).

- Temperature Range (with Viton® backing): -0°F (-17°C) to 450°F (232°C).

Certificates Available:

- FDA Extraction Studies per 21CFR177.2600 (elastomers) and 21CFR177.1550 (PTFE)

- Testing according to USP Chapter <87> and Chapter <88> Class VI

- ADI Free

- RoHS Directive 2011/65/EU and 2015/863

- Other certifications available upon request

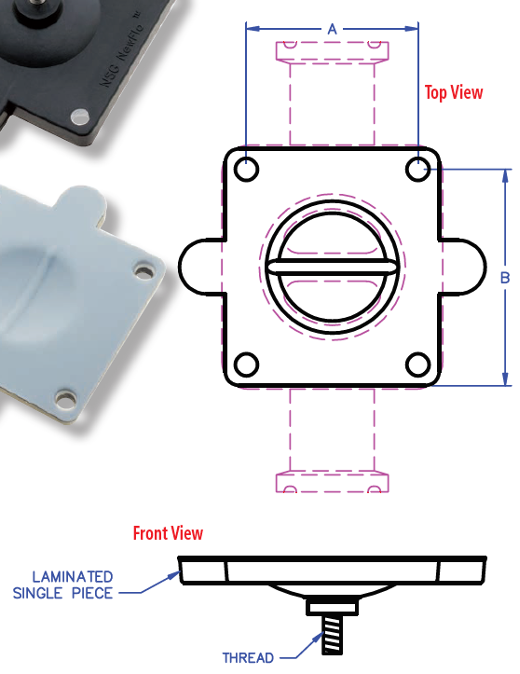

| Newman Part # | OEM Part # | A | B | Fastener | Availability |

| NGU-08-RX-E1 -S | 600/008/M17 (3,16,13) | 0.9 (22MM) | 0.9 (22MM) | Button | Stock |

| NGU-10-RX-E1-S | 600/010/M17 (3,16,13) | 1.5 (3914M) | 1.7 (44MM) | M4x .7 | Stock |

| NGU-25-RX-E1-S | 600/025/M17 (3,16,13) | 2.1 (54MM) | 1,8 (46MM) | Jan-20 | Stock |

| NGU-40-RX-E1-S | 600/040/M17 (3,16,13) | 2.8 (70MM) | 2.6 (65MM) | Jan-20 | Stock |

| NGU-50-RX-E1-S | 600/050/M17 (3,16,13) | 3.2 (82MM) | 3.1 (78MM) | Jan-20 | Stock |

| NGU-80-RX-El-S | 600/080/M17 (3,16,13) | 5.0 (127MM) | 4.5 (114MM) | 5/16 - 1 8 | Stock |

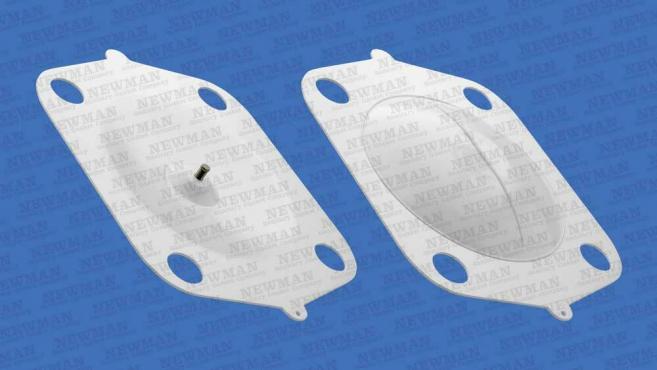

Single Piece Diaphragms for Gemü™ Valves

Genuine Newman 2107 EPDM (Ethylene Propylene Diene Monomer)

Genuine Newman 2107 EPDM is the material of choice for many food and biopharma processing applications, surpassing other EPDM’s on the market for decades in performance and reliability. An excellent general purpose elastomer, resistant to many chemicals, polar solvents, many CIP solutions, and most aqueous-based systems. Used for general processing, acid/alkalis, hot water and occasional steaming. Low permeability to gases. Useful in higher pressure and vacuum applications.

- Temperature Range: -20°F (-28°C) to 300°F (148°C) *

- Continuous Liquid Media: -20°F (-28°C) to 200°F (93°C) *

Genuine VITON® GF (FKM)

Genuine Dupont VITON® GF is the ground-breaking material of choice for more extreme food and biopharma processing conditions, only offered through Newman. An excellent overall elastomer, resistant to a wide variety of chemicals, polar and non-polar solvents, CIP solutions and aqueous-based systems. Used for general processing, most acids and bases, hot water and excellent steam resistance. Low permeability to gases. Useful in higher pressure and vacuum applications where both the sealing properties of rubber and the chemical resistance of Teflon® like materials are required.

- Temperature Range: 18°F (-7°C) to 450°F (232°C) *

- Continuous Liquid Media: -0°F (-17°C) to 300°F (148°C) *

We guarantee highest quality sanitary elastomer parts available on the market.

Quality Assurance

Rigorous Testing

Inspection

Newman Sanitary Gasket Company is a leading manufacturer of FDA and USP Class VI seals for High Purity Process applications such as the Pharmaceutical, Food & Beverage and Dairy industries. Newman Diaphragms provides world class replacement diaphragms for ITT®, Gemü®, Saunders® and Aquasyn® valves.